At Andrew Plastics, we’re specialist plastics manufacturers. With that in mind, we offer a wide range of services for our customers to take advantage of. Of course, plastic injection moulding is at the forefront of everything that we do but we also offer other services that can help meet all product specifications and needs.

Injection mould tooling and tool trialling are two areas that our expert team can help you with. But what are they? How do they work? And how can your business benefit from them? Don’t worry if you’re not sure, this post will explain all that you need to know about both areas and what you can expect from the service.

Plus, we’ll introduce our business throughout and provide a level of transparency into how we’d deal with similar projects and scenarios. The appetite for the level of investment in tooling required is also determined by the potential unit price required. The normal rule is that a more expensive tool should result in a reduced unit price. For example, a single impression tool will be cheaper to produce compared to a multi impression tool for the same product but there will be a trade-off with the cost of the subsequent manufacture of the required products. Therefore required future volumes and timescales will need to be factored in when deciding upon the complexity of the tool to be designed – all of which will impact the initial price of the investment.

We’ll cover:

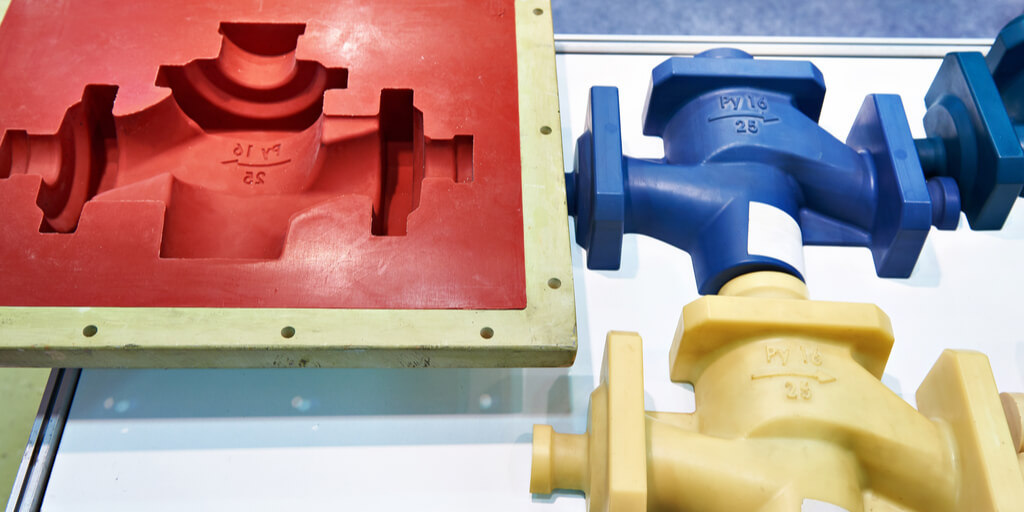

Within the plastic injection moulding process, bespoke moulds play a huge part. They’re a crucial piece of equipment that helps shape the end product to your desired needs. Should your moulds be poorly designed, you’ll end up with a lacklustre end product and won’t be happy with the finished article. That’s why you need to work with a manufacturer you trust to get them right.

Typically, moulds consist of both movable and fixed platens that help shape the materials during the manufacturing process. The materials are then clamped within the mould to ensure that they’re being shaped properly. During the process, the material will experience consistency and temperature changes before being released, so your moulds need to be up to this challenge.

The material used for each mould is dependent upon the volume of the order. Of course, we aim to make each process as cost-effective as possible, so we’d always advise on creating moulds that are built to stand the test of time – especially if you’re mass-producing. Whereas, if you’re only producing one-off products, less resilient materials are adequate.

Ensuring that your moulds are of a high standard is crucial. Quite simply, if your mould is off the mark, so will the finished product. But you needn’t worry about that – at Andrew Plastics, we ensure that all jobs are treated with the same level of professionalism, therefore, high standards can be achieved across the board in all projects.

Of course, we don’t expect our customers to be experts in plastic manufacturing – that’s our job. Therefore, we can’t expect you to approach us with clear ideas and specifications. If you can, that’s brilliant. However, if you have a vague idea, that’s also fine. We’ll work hard alongside you from initial concept to final sign off and ensure all requirements are met.

Our team of experts are vastly experienced. We’ve worked on many projects that span a wide range of industries, so we’re confident that we can accommodate your requests and needs. Bespoke is our standard – and that’s something that we practice in everything that we do.

At Andrew Plastics, we set the bar incredibly high. Due to our state-of-the-art premises, the quality of our work is unrivalled. Filled with industry-leading equipment, you can have every confidence that our expert team will be able to exceed your expectations. Quality is one of the main pillars of a successful mould tool, therefore, we always prioritise it.

We provide each project with a duty of care and attention that it deserves. Quite often, businesses tend to prioritise the jobs that are of huge monetary value to them. However, we can confidently say that we treat all jobs with the same level of professionalism and attention – no matter how big or small.

There’s nothing more frustrating than investing time and money into developing a tool, only for it not to work as you need it to, is there? Well, with our tool trialling service, you can be confident that we’ll get the tool to the position that it needs to be in to start working properly. Tool trialling is the process of ensuring the quality of the tool and solving solutions for it to work as it should.

Quite often, tools will be developed by another manufacturer and brought to us because they’re not delivering properly. A lot of the time, it’s due to a misguided lack of knowledge as to why the components aren’t working to deliver high-quality results. Therefore, further research is needed into why it’s not fulfilling needs and expectations.

At Andrew Plastics, our expert team takes the time out to strip things back to the start and find out more about the tool. What is it? What do you need it for? What would you like to produce with it? We find that scratching beneath the surface is the best way to find out why tools aren’t working as they should be – the solutions are often easy.

We welcome all projects that feel they could benefit from our tool trialling service. Quite often, tool trialling is one of the most rewarding tasks to work on. It’s like a puzzle to us – why isn’t it working? And how can we help? Plus, we love the opportunity to dive deeper into the realms of what our customers do and find out more about them.

We’re very meticulous in our approach. When trialling, the wrong analysis could cause huge delays to projects – something that we indefinitely want to avoid at all costs (if we can). We focus on debugging the polymer, any necessary modifications, timescale needed to fix the tool and the financial requirements.

As in all of our services, we provide an honest and transparent relationship. We care about our customers and want to ensure that their tool problems are resolved in the most efficient manner possible. Whereas, some plastic manufacturers will wrongly advise customers just so that they can line their pockets a little more – this is a huge no-no for us.

Now that you’ve had a little insight into some of our key services, are you ready to hold a conversation with us about your upcoming projects? You can rely on us to get the job done – first time, every time. With our customers at the centre of everything that we do, you needn’t worry about anything!

Finding the right plastic manufacturer for your business isn’t easy, we feel for you on that one. However, you’re in luck! We’ve got background expertise and experience with a wide range of industries. Therefore, you can be confident that we have everything it takes to deliver high-quality products and hold a successful long-standing relationship.

It’s important to not rush into any decisions, which is why we encourage you to contact us today for an in-depth chat! However, if you’d like to do a little more research before holding any initial conversations, we’ve created a free guide that outlines everything you need to know about us.

From who we are, how we work and much more – it’s all in there for you to benefit from. Grab your copy today!

LLorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris feugiat risus eros, nec fermentum. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Download Now

Injection moulding is a manufacturing process used universally

Read more

Of course, we all know the term ‘plastic’

Read more

At Andrew Plastics, we’re specialist plastics manufacturers. With

Read more