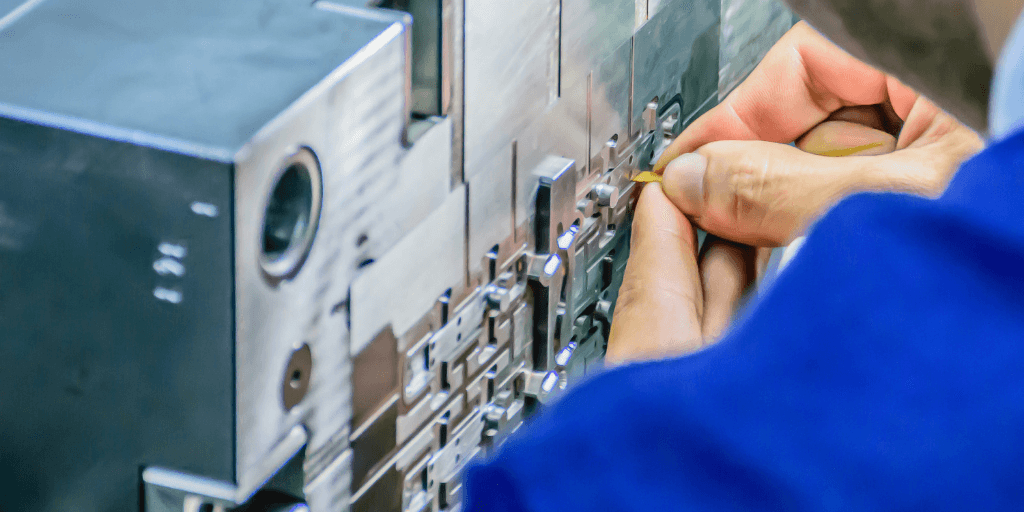

Our expert team are vastly experienced and possess an incredible wealth of knowledge to uphold impeccable standards at all times. Our tool-making service is first-class and it’s easy to see why we’re leading the way in various industries.

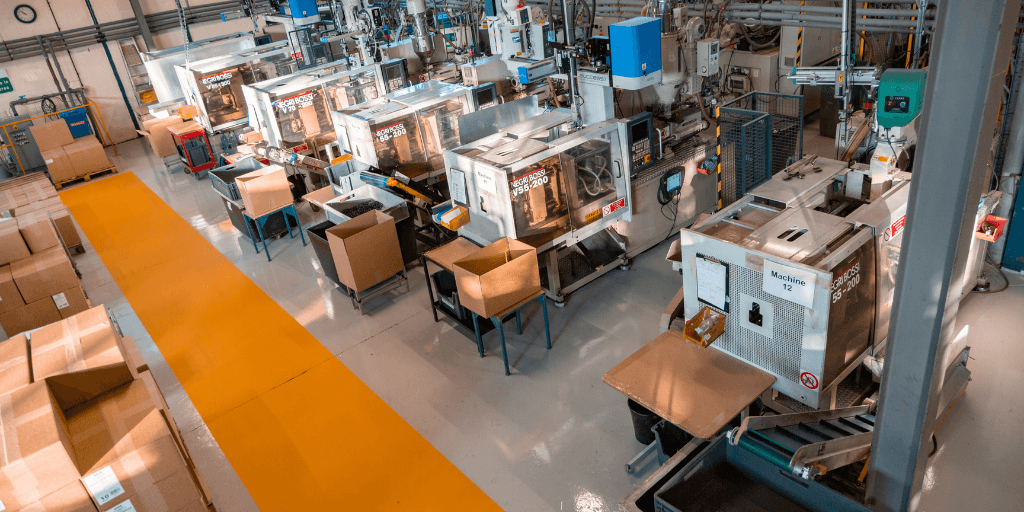

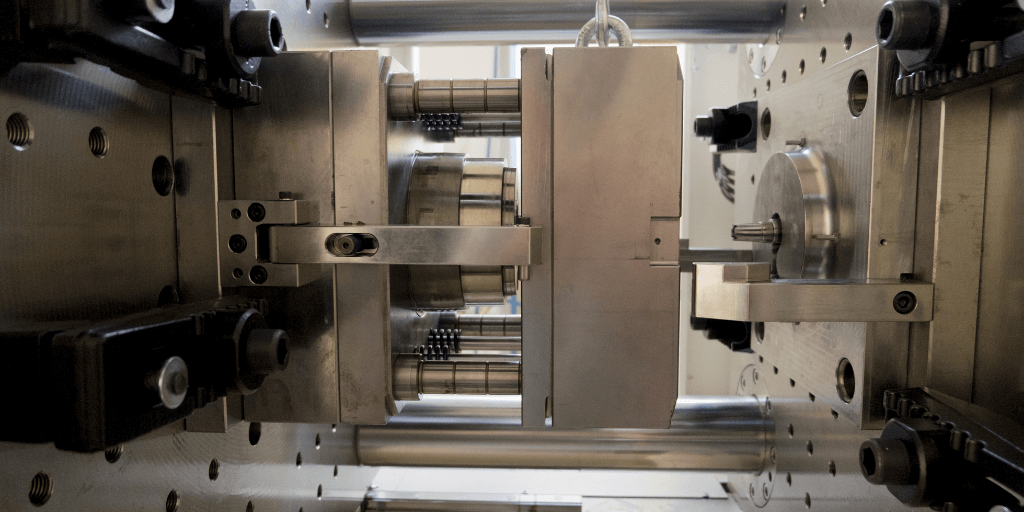

Our state-of-the-art plastic injection tool-making workshop is the perfect working environment to deliver high standards. It’s kitted out with upgraded lathes, surface grinders and spark erosion machines. Currently, it accommodates over 250 tools – both owned or on behalf of our clients.

We are particularly proud of the facilities now on offer within our Tool Room, having made significant investments in obtaining 2 new Hurco CNC machines, an EDM spark erosion machine, various testing equipment (including high-pressure water testers), and a new crane lifting system. As well as investing in state-of-the-art hardware, we have also acquired an experienced Tool Maintenance Engineer and CNC Operative to make the operation fully scalable and to truly provide a business partnership with you, keeping you fully informed along the development journey.

We use Fusion 360 and Precise 360 – enabling full transparency of work undertaken and ensuring complete interface between 3D design drawings through to tool production, thus minimising error, and maximising effective communication chains.

We work to a mantra of “first time, on time” in everything that we do – and our tool-making is no different. Our highly experienced and industry-standard qualified team hold incredibly high standards and work hard to add value for our customers at any given opportunity. That way, achieving your overall goals is no problem at all.

We pride ourselves on our ability to offer our customers the most efficient and effective tool-making processes. You can be confident that our team can meet your specific requirements and exceed all expectations. Andrew Plastics are well renowned for consistent and high-quality manufacturing.

The services we can offer in our Tool Moulding Workshop are:

We are a well-established business based in the North West of England and are ideally placed should you wish to reshore your tooling and manufacturing supply chain back to the UK.

Injection moulding is a manufacturing process used universally

Read more

Of course, we all know the term ‘plastic’

Read more

At Andrew Plastics, we’re specialist plastics manufacturers. With

Read more