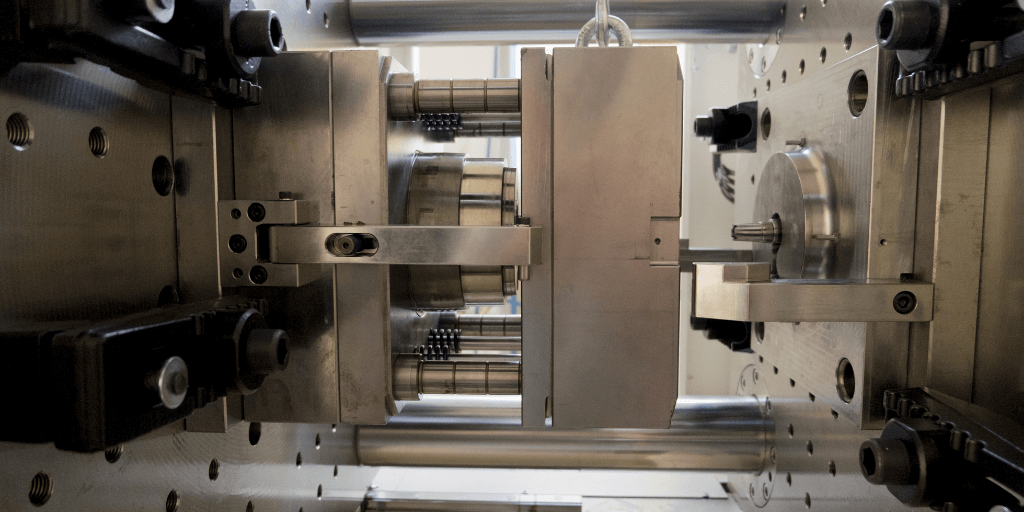

Not only do we test the performance of the tool, but the type and quality of plastic used as part of your injection moulding process; testing critical variables such as temperatures and pressures applied.

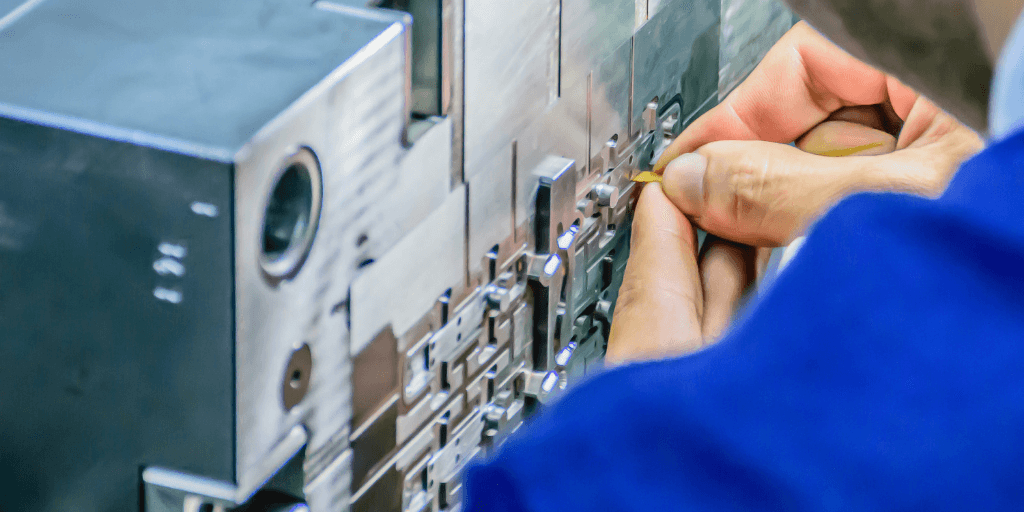

As this is a key area of your business, you are allocated a direct relationship to one of our qualified technical engineers. They’ll work alongside you closely, ensuring that they test and report directly back to you and full transparency is always upheld regarding performance.

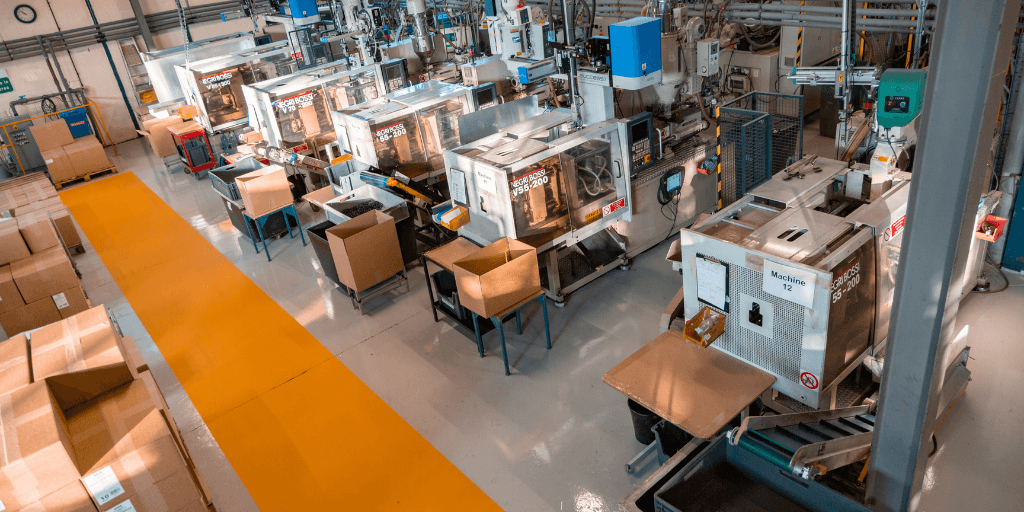

Once the trialling process has been completed and any performance issues have been rectified, you are free to pick up your tool. Alternatively, you can leave your tool on site where you can take advantage of our manufacturing facilities.

We also provide a tool servicing function whereby we can ensure continued maximum efficiency and prevent any potential costly malfunctions – giving you enhanced peace of mind.

If you have any untested new tools, why not use our trialling facilities to ensure our stamp of approval before you roll out to full production? That way, you can minimise or eliminate any costly production downtime and wastage.

Our trialling service goes hand in hand with our in-house enhancements and consultancy. We can recommend any improvements based on performance issues that might not have already been identified or considered? Overall, this results in a higher-quality product.

We work tirelessly alongside our partners and truly care about your requirements and needs. Unfortunately, that can’t be said about many businesses within the industry – but that’s where we excel and prove our worth. Your considerations matter and meeting all of your expectations is paramount.

Injection moulding is a manufacturing process used universally

Read more

Of course, we all know the term ‘plastic’

Read more

At Andrew Plastics, we’re specialist plastics manufacturers. With

Read more