Injection moulding is a manufacturing process used universally to manufacture various everyday goods. This manufacturing process is time-efficient, cost-effective and can produce parts on a mass scale. Through careful planning and consideration, the overall cost of this manufacturing process and production can be reduced. Without sacrificing quality, consistency and lead time.

The most common barrier to using this process is the available budget. But with the help of this post, you’ll be able to understand the factors that can affect the final cost of producing your tooling and the finalised product. The budget needs to cater for the design, tool manufacturing and the production of the tooling.

There’s a lot to consider but fear not, in this post we’ll be completely transparent with you. We’ll run you through the different factors that will affect the overall price and cost of the total job. That way, you’ll be able to make a finalised decision with the output being completely accurate.

We’ll cover:

There are several main cost increases included within injection moulding projects. Sometimes they’re often overlooked but if you’re focused on your budget, they’re worth noting.

Rest assured, you don’t need to be put off by the price. There are many methods and best practices you can apply to reduce the costs of injection moulding. That way, it’ll be a more cost-effective solution whilst still providing excellent results. We’ll explore some of them here.

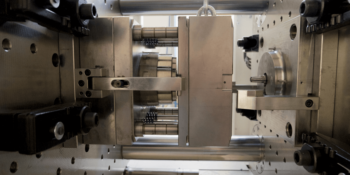

The initial costs for setting up injection moulding are usually more expensive than other alternative methods. This part of the process can’t compromise on accuracy, it needs to be spot on. This includes the design and consultation process as well as making the mould. The mould needs to be robust and durable to withstand several uses and replication.

Because of this initial upfront cost, many companies that use injection moulding will mass-produce products. Over time, this will reduce the overall unit costs.

This is the factor that will impact the design the most. A simple open and close tool will be significantly less costly than a complex design with multiple features and fonts.

Consider the different features that will need to be included in the mould. If you’re looking to save money, a simpler design can help reduce the overall manufacturing costs. Moulding numbers and company logos are unique and great branding techniques but these can be costly additions.

The more material required to make the tool, the more costly it will be to produce.

Of course, the more products that are made from the initial mould, the cheaper it will be. But if you can reduce the overall size of the mould, you’ll be well on your way to securing a cheaper overall price.

Injection moulding tools are made from different materials depending on their complexity, their frequency of use and planned longevity.

The type of plastic used for the product and the type of material used for the mould can all make a huge difference to the final costs. The more demanding a product requirement is, the greater the material costs. If you’re wanting to use different colourants and pigments, you’ll need to budget this too.

A simpler design will equal a cheaper outcome with maximised accuracy.

That’s right, if it’s not essential, don’t bother.

Although cosmetic finishes can be a great addition to the final product and improve the quality – it can also elevate the cost. Textured surfaces drive up tooling costs and require additional elements such as photo etching and mirror polish – just to name a few.

If these can be avoided and aren’t necessary, you’ll be able to cut back on the cost. But don’t worry, if your mould is accurate from the get-go, so will your products.

The price of injection moulding varies with every project. Without specific information about your products, it’s very difficult to give a definite answer on this. The initial upfront cost of the mould and tooling is high but pair that with the greater number of parts being produced and you’ll lower the overall unit costs.

If you’re wanting to produce products over and over again on a mass scale with complete accuracy – plastic injection is the best process. Mass-produced parts often use injection moulding as it’s the most economical and timely way to produce plastic products at high volumes.

One area that is often overlooked is the whole life cycle of this manufacturing process. By their nature, injection moulding tools have a high cost of entry but the production cost is much lower.

Injection moulding isn’t cheap but it guarantees the most precise outcome. It’s perfect for mass production, intricate details and robust products. As an example, if you’re going to be making more than 1000 parts per year for some years, it could cost between the region of £3,000-20,000. But of course, this all depends on the products being produced, how many are being produced and the finalisation of the design.

This can be quite a shock for people who aren’t familiar with injection mould tool making. But rest assured, this isn’t an exact figure. It’s a rough idea so you can see the difference between the pricing and the budgets that should be made available for this process.

Injection mould tool making is a flexible manufacturing process that can be adapted and changed over time. So if you’re looking at cutting back the costs it’s worth taking note of all the features we’ve mentioned.

We hope this has given you an insight into the different factors that can contribute to the overall cost of plastic injection moulding. From initial concept to manufacturing and output. It’s a lengthy process but with the right expert team on hand to guide you through, you’ll be producing the best product possible in line with your proposed budget.

If you want to learn more about the plastic injection tool moulding process, then look no further. You can download our FREE Ebook today and learn everything you need to know about the process, the industries that can benefit and much more. Start learning today!

LLorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris feugiat risus eros, nec fermentum. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Download Now

Injection moulding is a manufacturing process used universally

Read more

Of course, we all know the term ‘plastic’

Read more

At Andrew Plastics, we’re specialist plastics manufacturers. With

Read more